Guardians of the Game

by Stacy Rinella | May 13, 2024 7:00 am

[1]

[1](3 million sf) with an expandable seating capacity of up to 100,000.

Photos courtesy Sightline Commercial Solutions

In the landscape of sports and entertainment, the spectator experience has undergone a profound transformation. As arenas strive to captivate and engage increasingly discerning audiences, the evolution of sports stadiums has become emblematic of this shift. Amid this evolution, one often overlooked yet crucial aspect is the role of metal infrastructure, particularly in the form of railings and bleachers.

Safety in numbers

Gone are the days of passive viewership. Today’s spectators seek an immersive and interactive experience. As sports stadiums evolve into multifaceted entertainment hubs, the demand for structural integrity and safety has never been more paramount. It is not merely about the game anymore; it is about crafting an atmosphere where fans experience both exhilaration and security, often without realizing the latter.

Enter metal, the unsung heroes of stadium architecture. These components not only provide sturdiness and support, but also serve as the backbone of the venue’s structural integrity. In a world where “safety in numbers” is more than just a saying, these metal elements ensure large crowds can gather confidently, knowing they are well-supported and protected.

So, what goes into the intricate design and engineering behind these metal structures? From their robust construction to their seamless integration the use of metal marries functionality and aesthetics in stadium architecture.

[2]

[2] [3]

[3]Stadiums in the spotlight

Bill Snyder Family Stadium

In Manhattan, Kan., Bill Snyder Family Stadium stands as a revered venue for football, serving as the home field for the Kansas State University (KSU) Wildcats football team.

With a seating capacity of 50,000, Bill Snyder Family Stadium ranks as the eighth largest among current Big 12 members. Bill Snyder Family Stadium underwent a $52 million renovation in August 2021, modernizing the stadium and transforming the gameday experience. A pivotal component of this overhaul was the installation of 1,179 m (3,867 ft) of custom fabricated metal railing. Provided by Sightline Commercial Solutions, these railings are prominently featured throughout the main concourse, and are also installed in the north concourse stands along with the west and east entrances of the Bramlage Coliseum.

Beyond pure functionality, the railings add a touch of modernity and sophistication to the stadium’s overall ambiance, elevating the gameday experience for generations of Wildcat fans.

Gainbridge Fieldhouse

Home to the Indiana Pacers in Indianapolis, Ind., Gainbridge Fieldhouse, features drink rails, structural glass railing in aluminum shoe, and welded aluminum two-line aisle railings by Tuttle Railings, a division of Dant Clayton. Despite challenges such as a compressed two-year schedule and the need to install 24 different rail types, Tuttle, a fabricator of non-ferrous welded and mechanical hand railings, completed the project on time and under budget. “Every stadium owner should consider the advantages of the longer life span of aluminum rails,” says Tom Moon, commercial sales director for Tuttle. “The small increase in cost is justified when considering it’s a safer, more sustainable and long-lasting solution.”

[4]

[4] [5]

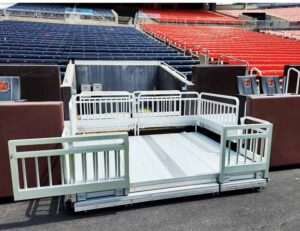

[5]Cleveland Browns Stadium

Sightline Commercial Solutions collaborated with seating provider DreamSeat at Cleveland Browns Stadium in Ohio to provide the stadium’s metal railings. The use of 3D laser scanning technology to capture precise measurements for custom VIP seating systems, the incorporation of weather-resistant aluminum platforms, and clear anodized guardrail demonstrate a focus on durability and safety. These materials not only enhance the viewing experience but also ensure the longevity of the seating areas.

Further, camera platform areas with attachments for field pads and mounts accommodates modern technological needs, such as filming and photography during games.

[6]

[6]SoFi Stadium

In Inglewood, Calif., SoFi Stadium holds the title as the NFL’s largest venue, spanning more than 278,709 m2

(3 million sf) with a seating capacity of up to 100,000. Home to the Los Angeles Rams and the Los Angeles Chargers, this mixed-use sports and entertainment venue required an unprecedented amount of railing—22,250 m (73,000 ft)—making it Sightline Commercial Solutions’ largest commercial railing project to date.

The custom-designed and engineered railing can be found both inside and outside the stadium. The railing, totaling 22 km (14 mi) in length, includes cable, glass, aisle, and cane railings, all made of sleek and sturdy aluminum. These railing types were deployed in 125 different configurations throughout the stadium, providing safety and aesthetics in the seating bowl, suites, concourse, vomitorium areas, monument stairs, and canyons on each side of the facility.

[7]

[7]Purdue University’s Ross-Ade South End Zone

Tuttle’s project at Ross-Ade South End Zone in West Lafayette, Ind., was completed on time and under budget. Ken Swan, senior project manager at construction firm, AECOM Hunt, which spearheaded the project, says, “It was an incredibly tight schedule. The job was awarded in February 2023 and completed in time for the home opener in August.”

The project involved installing 12 different rail types, spanning 2,408 m (7,900 ft). Despite the complexity and compressed schedule, the entire project was completed in time for the season. The installation included aluminum safe standing rail, aluminum picket rail, and aluminum drink rail, meeting diverse design requirements.

Other notable projects

At Kauffman Stadium, Tuttle provided custom welded aluminum rails. In Washington, D.C.’s Verizon Arena, Tuttle installed structural glass railing in aluminum shoe, welded aluminum two-line aisle railings, and welded aluminum five-line rod infill railings. At Hinkle Fieldhouse in Indianapolis, Ind., Tuttle installed structural glass railing in aluminum shoe, welded aluminum two-line aisle railing, and welded aluminum vertical picket railing.

Expert insights on railing standards

In 2022, in an in-depth examination titled “Enhancing Railing Safety in Sport/Concert Venues,” authored by Drs. Gil Fried, Salih Kocak, and Aneurin “Nye” Grant from the University of West Florida, critical insights were provided into safety concerns surrounding railing heights in sports venues. The article examines past incidents of injuries and fatalities resulting from falls over low railings. It analyzes factors such as railing height, material strength, and crowd behavior, advocating for stricter standards and innovative design approaches to address safety hazards.

Metal Architecture spoke with the authors, who provided invaluable insights into the safety, science, and integrity of metal railings, and how best to ensure a safe fan experience over time. Dr. Gil Fried, interim assistant dean of the College of Business, emphasizes the significance of monitoring incident reports beyond metal fatigue. He says, “The key is to monitor incident reports that arise throughout the venue and determine where there might be specific issues.” He added that several other factors, such as the railing height, location, diameter, aisle way, seat size, and the activity taking place, should also be analyzed when identifying possible safety concerns.

Dr. Aneurin “Nye” Grant, associate professor in the Department of Mechanical Engineering, provided insights into the inadequacy of current guardrail standards. He stated, “In every reference we looked at, there is a near universal agreement that a 660 mm (26-in.)

line-of-sight guardrail exception is inadequate for safety purposes.” Dr. Grant emphasized the discrepancy between existing standards and safety requirements, noting guardrails are typically required to be 1,067 mm

(42 in.) according to the International Building Code (IBC) and Occupational Safety and Health Administration (OSHA) standards. He highlighted the rarity of incidents involving falls over a 1,067-mm (42-in.)

guardrail and underscored the necessity of aligning guardrail standards with safety principles. He concluded, “A 660 mm (26-in.) rail contradicts everything we know about safety, physics, and common sense.”

Accounting for impact

Dr. Salih Kocak, assistant professor in the Department of Mechanical Engineering, emphasized the importance of advancements in metal alloys for railing systems. He says, “I firmly believe the metal alloys and fabrication techniques are sufficient to provide adequate safety and longevity for the railing systems when constructed properly.” Dr. Kocak also highlighted the need for reconsidering design loads, noting current standards do not account for impact loads during events. He suggested, “The impact loads, including impact mass, impact velocity, and impact angle should be considered in the design process to enhance the safety and longevity of railing systems in sports and entertainment venues.”

- [Image]: https://www.metalarchitecture.com/wp-content/uploads/2024/05/Fig9_Sofi_Aerial2.jpg

- [Image]: https://www.metalarchitecture.com/wp-content/uploads/2024/05/Fig1_KSU_WestEntrance.jpg

- [Image]: https://www.metalarchitecture.com/wp-content/uploads/2024/05/Fig2_KSU_CustomFabricatedRailing.jpg

- [Image]: https://www.metalarchitecture.com/wp-content/uploads/2024/05/Fig5_CBS_CameraStand.jpg

- [Image]: https://www.metalarchitecture.com/wp-content/uploads/2024/05/Fig7_CBS_RailingsAesthetic.jpg

- [Image]: https://www.metalarchitecture.com/wp-content/uploads/2024/05/Fig10_Sofi_Railings.jpg

- [Image]: https://www.metalarchitecture.com/wp-content/uploads/2024/05/Purdue-University-Ross-Ade-Stadium-Renovation-5.jpg

Source URL: https://www.metalarchitecture.com/articles/guardians-of-the-game/