Raising the Bar on Snow Retention Systems

by hanna_kowal | January 7, 2026 4:13 pm

[1]

[1]Photo courtesy S-5!

Rooftop avalanches remain an ongoing concern for the design community—leading to hundreds of millions of dollars in property damage, personal injuries, and even fatalities each year. As both a life-safety issue and a potential source of liability, effective mitigation is essential in roof system planning.

Snow guards, designed to hold snow in place on a roof until it melts gradually, are a critical component in modern metal roofing assemblies. Despite their critical role, snow retention systems have historically operated in a regulatory gray area, lacking specific guidance in major building codes with dedicated performance metrics. The result has been market confusion, permitting delays, exaggerated or irrelevant product claims by vendors, and, in many cases, system failures.

[2]

[2]Photo courtesy S-5!

This lack of clarity has created challenges for architects and specifiers, who are increasingly responsible for designing to ever-higher standards of safety, durability, and performance. In the absence of prescriptive code language, there are key considerations for design professionals to ensure the snow retention systems they specify will perform as intended.

In recent years, forward-thinking manufacturing has begun to close this gap by subjecting products to rigorous third-party testing, aligning with established engineering principles, and pursuing credible third-party certifications and transparency. These efforts are defining a new standard for performance, safety, and reliability in snow guard systems. Today, these benchmarks are no longer optional; they are critical.

A historical gap in snow retention standards

[3]

[3]aftermath of a rooftop

avalanche.

Photo courtesy S-5!

The metal roofing industry has made significant strides in engineering, sustainability, and building envelope integration. However, planning snow retention has often lagged behind. It is often added late in the process or left to contractors to resolve in the field. Without standardized testing protocols and code-prescribed design criteria for snow guards, many products have entered the market with performance claims that are more based on marketing than on prudent engineering.

This has led to widespread inconsistencies in product quality and reliability. In some cases, systems have failed when exposed to snow loads they were never truly tested to withstand. The consequences are serious: personal injury, property damage, legal claims, and potential liability for the design team.

Fortunately, some progress is being made to close this gap through established testing protocols, independent evaluation criteria, and structural performance validation that align with accepted engineering practices.

Certified testing: designing for real-world conditions

Snow retention systems should be tested to withstand real-world conditions, including:

- forces induced by project-specific drag loads of sliding snow

- materials compatibility and corrosion resistance

- designs that accommodate the roof’s thermal cycling (when appropriate)

[4]

[4]This image captures the aftermath of a rooftop avalanche. Photo courtesy S-5! - long-term waterproof integrity

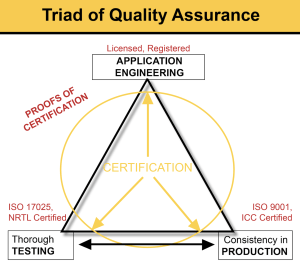

To ensure reliability, snow retention systems should be load-tested using actual metal roof panels that match specific profile geometries, gauges, materials, and coatings. Testing should occur in a Nationally Recognized Testing Laboratory (NRTL) accredited to the International Organization for Standardization (ISO) 17025 or an equally rigorous standard, to ensure the highest level of credibility and accuracy in test results across the industry.

A snow retention manufacturer should provide proof of design using specific load test data of the exact roof product and application, rather than on data extrapolated from products that merely appear similar. This helps specifiers confidently determine the number and spacing of snow guards required to meet the expected design forces in a given application.

P.E.-stamped reports

If project-specific testing and analysis are required, manufacturers should provide professional engineer (P.E.)-stamped reports that are valid in the jurisdiction where the project is located. This documentation helps streamline approval by authorities having jurisdiction (AHJs) and protects the design team from upstream liability.

Critical certifications for snow retention on metal roofs

[5]

[5]Photo courtesy S-5!

While snow retention systems are not explicitly addressed in the International Building Code (IBC), recognized certification bodies now offer evaluation criteria that serve as code-equivalent pathways for compliance. These provide an objective framework to validate the design, safety, structural integrity, and manufacturing quality of attachment systems for metal roofs.

Among the most relevant for snow retention are the International Association of Plumbing and Mechanical Officials (IAPMO) Evaluation Criteria (EC) 029 and International Code Council Evaluation Service (ICC-ES) reports. In the absence of a building code that covers snow retention, compliance with the IAPMO EC 029, Evaluation Criteria for Metal Roof Attachment Methods for Photovoltaic Module Mounting Systems, Snow Retention Systems, and Other Accessories, is considered code-equivalent. EC 029 Evaluation Reports (ER) from IAPMO may be utilized by specification to qualify proper design, testing, and production of snow retention systems, and are widely accepted by jurisdictional code compliance agencies. In contrast, other means of evaluation often are not. Issued by the ICC-ES, reports independently verify that a product complies with applicable codes and technical standards. For snow retention systems, the reports often include detailed findings, conclusions, and recommendations from a particular evaluation. They also outline the requirements or acceptance criteria used to evaluate a product, as well as the procedures for identifying and installing it.

Meeting such criteria offers specifiers a clear, defensible path to product selection, especially in jurisdictions with heightened scrutiny or where insurance and liability concerns are high.

Manufacturing standards and material integrity

The performance of a snow retention system depends not only on its design but also on the consistency of its manufacture and the traceable quality of its materials. For this reason, architects and specifiers should prioritize systems produced in ISO 9001:2015-certified facilities. This globally recognized standard demonstrates a commitment to key quality management principles—such as continuous improvement, risk management, customer focus, and corrective action procedures—which help reduce defects, delays, and variability in production.

[6]

[6]Photo courtesy S-5!

Often a prerequisite for competitive bids, contracts, and strategic partnerships, manufacturing in an ISO 9001:2015-certified facility ensures reliability and commitment to quality. It also supports robust, repeatable manufacturing processes that standardize operations to minimize errors and defects.

Equally important is material certification. It is critical to use certified materials that are precisely the same as those validated by testing, typically accompanied by documentation such as certificates of compliance, test results, and inspection reports, which confirm adherence to relevant standards. Periodic proofs over time are also advised to ensure the materials’ certification status and compliance are maintained.

All components should be fabricated from material certified to ASTM standards, with full traceability and documentation. Commonly applied material standards include:

- Extruded structural-grade aluminum components should be made from 6000-series alloys.

- Cast aluminum components should meet ASTM B26/B26M, B108/B108M, or B85/B85M.

- Plate and sheet aluminum components should meet ASTM B209.

- Brass components should meet ASTM B927/B927M.

- Stainless steel components should be 300-series alloy and meet ASTM A276/A276M.

Design support and resources

Performance claims are only meaningful if they are supported by accessible data, engineering documentation, and responsive technical support. A trusted attachment technology provider must both demonstrate product quality through testing and support it with accessible design resources and knowledgeable support teams to help architects and specifiers confidently integrate their products into construction documents.

A comprehensive suite of documentation and digital tools should be available for informed decision-making and successful project execution in real-world conditions, including:

- product load tables and layout calculators

- Building Information Modeling (BIM), specification, and design software

- engineering test data and certified reports upon request

- product data sheets

- P.E.-stamped, project-specific calculations

- technical bulletins and installation instructions

- project-specific design assistance

- long-term material warranties

- optional “installed system” performance warranties

Whether designing for a high-snow area in the Rocky Mountains or retrofitting an existing metal roof in the Northeast, these tools help streamline coordination, ensure accurate specification, and support proper installation in the field.

Liability reduction and code compliance

Ultimately, the responsibility for specifying a safe and effective snow retention system lies with the design team. In the absence of explicit code mandates, liability risk increases, especially when a product’s performance cannot be verified.

By selecting systems that have been structurally tested, independently certified, and supported by transparent documentation, architects and specifiers can significantly reduce that risk. Not only does this approach align with best practices in building envelope design, but it also helps simplify plan review, ease contractor coordination, and protect the design professional should issues arise.

Raising the standard for snow retention

Snow guard systems should never be an afterthought or treated as simple components; they play a critical role and deserve careful consideration. As building codes evolve and performance expectations rise, snow retention systems must be treated with the same rigor as any other structural or life-safety element in roof design.

Architects and specifiers now have the tools to demand more: products that are tested, certified, and engineered to perform in real-world conditions. In a sector where the standards gap has long gone unaddressed, now is the time to demand more and choose solutions that meet the highest level of trust and performance.

Rob Haddock, CEO and founder of S-5! and director of the Metal Roof Advisory Group, is a former contractor, award-winning roof forensics expert, author, lecturer, and building envelope scientist who has worked in various aspects of metal roofing for five decades. S-5! is the first and only snow retention manufacturer to achieve an Evaluation Report of Compliance (ER) with the IAPMO EC 029–2018 industry standard for testing and certifying snow retention devices. For more information, visit S-5.com[7].

- [Image]: https://www.metalarchitecture.com/wp-content/uploads/2026/01/ColorGard2.0holdingbacksnow.jpg

- [Image]: https://www.metalarchitecture.com/wp-content/uploads/2026/01/image_123650291-1.jpg

- [Image]: https://www.metalarchitecture.com/wp-content/uploads/2026/01/image_123650291.jpg

- [Image]: https://www.metalarchitecture.com/wp-content/uploads/2026/01/thumbnail_image_50435073.jpg

- [Image]: https://www.metalarchitecture.com/wp-content/uploads/2026/01/thumbnail_image_50416129.jpg

- [Image]: https://www.metalarchitecture.com/wp-content/uploads/2026/01/Triad-of-Quality-Assurance-011425-1.png

- For more information, visit S-5.com: https://www.s-5.com/

Source URL: https://www.metalarchitecture.com/articles/saftey-snow-retention-systems/