Small Things Can Make a Big Difference

by Stacy Rinella | January 28, 2025 7:22 am

[1]

[1]Owners and design professionals frequently rely on metal wall panel systems to create commercial building exteriors with a modern appearance and code-compliant performance that can be constructed quickly and operate economically. Understanding the critical connection between exterior wall panel cladding and attachment systems supports effective, energy-efficient metal building envelope designs.

Benefits and incentives

Energy-efficient building envelopes play a vital role in reducing climate change’s impact. According to the U.S. Department of Energy, by 2040, model energy codes for commercial buildings are projected to save:

- $78 billion in energy cost savings

- 375 million metric tons of avoided CO2 emissions

- 7.8 quads of primary energy

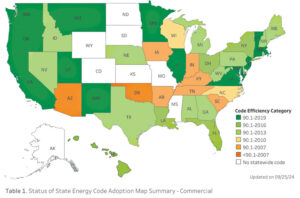

The Inflation Reduction Act (IRA) incentivized adoption of the latest model energy codes, which are the 2021 International Energy Conservation Code (IECC) and the ANSI/ASHRAE/IES Standard 90.1–2019. By September 2024, at least 15 states were using

90.1-2019 for commercial buildings.

[2]

[2]

To achieve projects’ energy efficiency goals, architectural design strategies include increased air tightness, high insulating performance (R-value) walls, exterior insulation, and reduced thermal bridging.

Thermal bridging occurs at localized areas where energy (heat) flows through walls, roofs, and other components. This can lead to higher operating costs due to the heat loss. Minimizing thermal bridging optimizes building envelope performance, saves energy, and reduces associated emissions. It also affects condensation and indoor air quality (IAQ), which impact occupant comfort, health, and well-being.

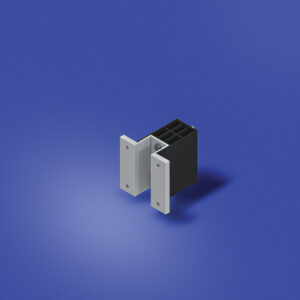

[3]

[3]features cladding attachments

manufactured with an

extruded aluminum clip and polyamide thermal break.

Three essential steps to thermal efficient solutions

To reduce thermal bridging in metal-clad buildings, follow these three steps:

- Use continuous insulation (c.i.)

- Use thermally efficient cladding systems and attachments

- Use thermally efficient materials

Continuous insulation, as defined by ASHRAE 90.1, goes across all structural members without thermal bridges other than fasteners, windows, skylights, doors, and building service systems. It is installed on the interior, outside the primary structure (wall sheathing), or it is integral to any opaque surface of the building.

[4]

[4]The IECC has required continuous insulation in the building envelope since 2012. Since 2018, the IECC has prescribed how much insulation is required for each of the eight U.S. climate zones and for various above-grade walls, below-grade walls, roofs, and floors.

Metal cladding systems and attachments are available in different materials: galvanized steel, stainless steel, aluminum, fiberglass, composites, and plastic. While all are engineered to support exterior wall cladding, their varying methods include continuous framing, intermittent clip and rail, long fasteners, masonry ties/anchors, or other engineered systems.

While aluminum composite material is the most popular cladding system, attachments should work for nearly any substrate, insulation, or cladding. Cladding attachments can be either horizontal or vertical applications.

Metal cladding attachments are highly conductive, allowing heat energy and air to bypass the thermal insulation and air-water barrier. Continuous Z-girts profiles, made with galvanized steel or aluminum, are the most commonly used cladding attachments, yet they can degrade the exterior insulation performance by up to 50 percent. Regarding prescriptive model energy code compliance, it is very difficult to meet effective R-value requirements with this system’s performance.

Fiberglass attachments can provide adequate performance, but this material requires training and personal protective equipment. This can add time to the schedule and cost to the installation.

Alternative cladding attachments are also available. One example is manufactured with an extruded aluminum clip and a polyamide thermal break. This attachment type significantly reduces thermal bridging, minimizing the exterior insulation performance degradation. It installs quickly without special equipment, meets low-emission testing requirements, and is not susceptible to electrochemical reactions, corrosion, or moisture.

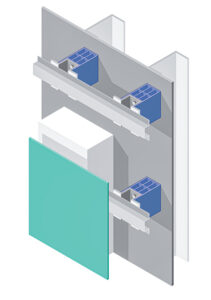

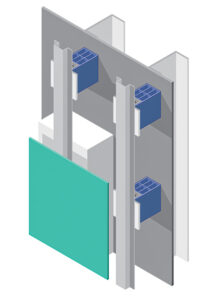

[5]

[5]efficient polyamide can help achieve aesthetic goals and performance requirements while saving time, labor, and energy costs.

[6]

[6]barrier, cladding attachments made with an extruded aluminum clip and a thermally

efficient polyamide mounting support maintain continuous insulation requirements.

Condensation considerations

In metal wall cladding systems, moisture from condensation typically results from thermal bridging, when the colder exterior temperature bridges through to the warmer interior, or when a chilled interior bridges to a hot exterior climate. The more moisture present in the air infiltrating a wall system by thermal bridging, the more condensation occurs. This can further degrade the cavity insulation’s thermal resistance.

Moisture buildup can destroy or diminish the building components’ integrity and compromise the building’s structural performance. It can rot wood, corrode steel, crack masonry, and delaminate fiberglass and other composite materials. It can seep into finished interior spaces, causing physical damage as well as creating visual stains. When mold develops, these stains can be accompanied by an unpleasant odor. Moisture-grown mold, mildew, and other microorganisms can negatively affect IAQ and occupants’ health.

Proven performance

Reviewing the performance data and test reports for cladding attachment elements will help ensure metal wall systems achieve the required results. In addition to thermal insulation and moisture management, it is essential to review air, water, structural, and

fire performance.

Choose cladding attachments tested to meet ASTM standards, such as ASTM E283 for air infiltration and ASTM E331 for water resistance. For added assurance, conduct air and water testing on a small-scale mock-up of the project-specific wall assembly in accordance with the Fenestration and Glazing Industry Alliance’s (FGIA) AAMA 501.1 standard test method.

National Fire Protection Association’s (NFPA) 285 provides a standard test method for evaluating the fire propagation characteristics of exterior, non-load-bearing wall assemblies with combustible components. NFPA 285 is an assembly test and not a component test. This means the entire exterior wall assembly must be evaluated for compliance rather than a single material or component located within an assembly. Putting safety first, select a cladding attachment that has undergone

NFPA 285 testing as part of a wall assembly.

Best practices

As building codes become more stringent and new technologies are introduced, construction best practices must follow. The more parts, steps, and complexity, the greater the likelihood of error.

It can be small details that make a big difference in a project’s installed performance and, by extension, its budget and schedule. With cladding attachments, for example, all fasteners should be driven perpendicularly to the substrate until they are flush with the air barrier membrane. Any variance in this can produce a hole larger than the fastener, creating avenues for air and moisture infiltration. Cladding attachments with screw guides ensure perpendicularity, saving time and future performance issues.

Under controlled conditions in a test environment, skilled installers used two different cladding attachments for a 21.8 m2 (135 sf) wall. The standard fiberglass attachment took four hours and 31 minutes to complete the wall installation. The aluminum with polyamide thermal break attachment took one hour and

15 minutes—more than three times faster.

Total value solution

Since value-engineering can be used to improve the project profitability, it makes good business sense—provided the proposed alternatives meet the same performance requirements for a “total value” solution.

Total value criteria for cladding attachments should be evaluated for:

- High thermal performance

- Fast, easy, accurate installation

and adjustment - Cost-friendly materials and

labor-saving solution

Thermal modeling is required to calculate cladding attachments’ performance but often is omitted during a project’s value-engineering process. The Building Envelope Thermal Bridging Guide and Thermal Envelope’s online tool[7] can help evaluate and calculate the wall cladding’s performance in new and existing construction. Installation comparison exercises also can inform decisions about the wall system’s optimal total installed cost. These small attachments can make a big difference in improving a metal-clad building’s thermal performance and ensuring the best total value.

Technoform’s William Green works with customers to help them develop industry-leading, high-performance products to meet energy performance needs and sustainability goals. He can be reached at

william.green@technoform.com.

- [Image]: https://www.metalarchitecture.com/wp-content/uploads/2025/01/2Technoform-WA-BullittCenter_Benschneider1.jpg

- [Image]: https://www.metalarchitecture.com/wp-content/uploads/2025/01/1DOE-OSECEP_CommercialPortal_crop.jpg

- [Image]: https://www.metalarchitecture.com/wp-content/uploads/2025/01/5Technoform_MA-DCAMM-installation.jpg

- [Image]: https://www.metalarchitecture.com/wp-content/uploads/2025/01/6Technoform-ThermalIsolatorClip.jpg

- [Image]: https://www.metalarchitecture.com/wp-content/uploads/2025/01/6Technoform-ThermalIsolatorClip_CladdingHorizontal.jpg

- [Image]: https://www.metalarchitecture.com/wp-content/uploads/2025/01/6Technoform-ThermalIsolatorClip_CladdingVertical.jpg

- Thermal Envelope’s online tool: https://thermalenvelope.ca/

Source URL: https://www.metalarchitecture.com/articles/small-things-can-make-a-big-difference/