Architects design environments to improve the quality of life, and a key aspect is to select the right material. One that has been gaining more attention for its aesthetics and versatility is expanded metal. Also known as architectural or decorative mesh, it is primarily chosen for its aesthetics, pattern uniformity, strength and is light weight. These characteristics make expanded metal an ideal material for both small- and small-scale ceiling panel systems.

Specifying and Installation

By its very nature, expanded metal has an open area percentage which can be modified to conceal, decorate, provide shade, privacy or ventilation, and more. The panels are suspended from the ceiling and will conceal conduit and HVAC systems, but lights and sprinkler systems can be above, below or even in between the panels in a linear fashion. Flattening the expanded metal will provide more views, whereas if it is left raised, lines of sight are directional—like those of louvers. Paint or powder coat can be applied and should be done after flattening and prior to installation. Aluminum is primarily used as it is the lightest metal. Steel is chosen for its superior strength, and stainless steel features a highly polished finish. Even copper and brass can be used for a stunning look.

Working with an expanded metal manufacturer will provide you with insights, answers to your questions, recommendations, and suggestions. The dimensions you will need to provide include:

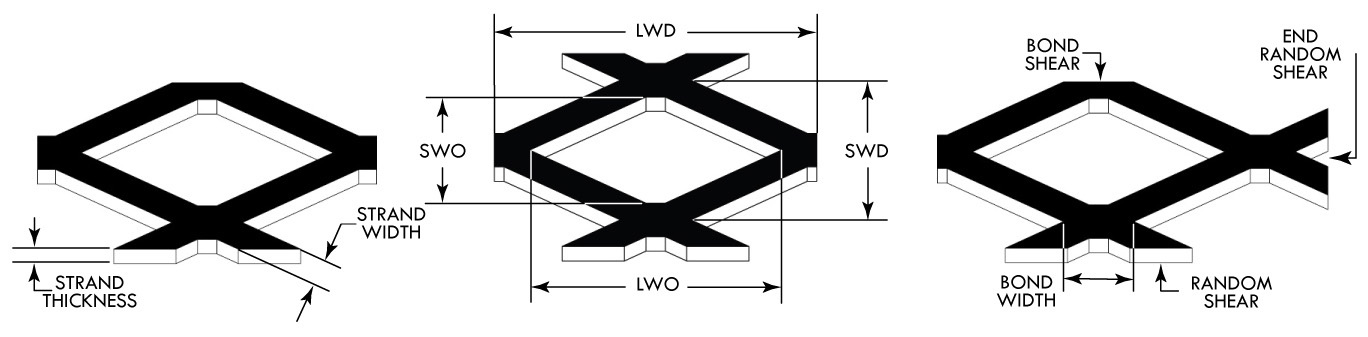

- LWD and SWD—long way and short way design of the diamond (or LWO and SWO—long way and short way opening of the diamond)

- Strand width

- Metal type and thickness

- Panel Length and width

- Raised or flattened

- Random shearing or bond shearing

- Optional paint or powder coat

An important consideration is how the ceiling panels will be installed in relation to the fire sprinkler system. If they are installed below the sprinklers, the openings must meet a minimum size or open area percentage to meet fire codes. This ensures the effective dispersion of water from the sprinklers.

For a seamless look where the ceiling panels abut each other, they are formed into a box with two installation options: The panel can either be slipped and crimped onto a frame or hooked to a substructure frame. Another installation option is to lay the panel into a frame. This allows for installation flexibility around lights, sprinklers and other structures. Inclusion of swing-down frames allow easy access for maintenance to substructures. For vents, patented four-way ceiling diffuser grilles can be used to complement the ceiling panels. Requiring only the replacement of the housing’s grille; there is no need to replace the entire unit.

Not limited to a square or rectangle, the ceiling panels can be cut and formed into shapes for a unique geometry. Even the openings are not limited to a diamond-shaped pattern, such as the Metal Architecture Readers’ Choice Award-winning Imperial and Apollo decorative patterns.

Environmental Advantages

The primary environmental advantage of expanded metal is its sustainability: it is 100% recyclable. The raw material is routinely sourced from metal suppliers that typically include 20 to 35% recycled metal, with some suppliers using up to 40%. In accordance with the US Green Building Council LEED 2009 recycled content requirements, high-recycled content steel contains 40 to 57.5% recycled content that can be utilized in calculating LEED MR Credit 4–Recycled Content.

The manufacturing process is also environmentally friendly. A metal coil is unwound and fed between a set of knives. Contrary to popular belief, the knives do not punch the metal. Rather, it is slit and simultaneously stretched producing expanded metal’s signature diamond pattern. This requires no additional parts or processes, yields more finished product from the raw, and produces little to no waste. Instead of being composed from separate strands, it is a single sheet that is lightweight, has an extremely high strength-to-weight ratio, and has no points that can separate.

Additional Architectural Uses

As façades or window panels, optimization of the strands and openings can dramatically reduce the sun’s radiant heat from entering a building. This can require the use of less energy to operate HVAC systems and may help earn both MR and EA LEED credits. Additional uses include sunshades, canopies, privacy panels, outdoor furniture, trellis and living walls, gates, fencing, stairs, railing, infill panels for cabinets, shelving and more, and you’re only limited by your imagination.

Manuel E. Menchaca, MBA, is the senior marketing manager at Wallner Expac in Ontario, Calif. To learn more, email mmenchaca@expac.com or visit www.expac.com.