The metal building industry has an exciting and promising future in sight. According to a 2022 study by Cohent Market Insights,1 the global metal building system segment is forecast to grow to $1.1 billion by 2030, up from $493 million in 2022. This represents a compound annual growth rate (CAGR) of 9.2 percent.

The metal building industry has an exciting and promising future in sight. According to a 2022 study by Cohent Market Insights,1 the global metal building system segment is forecast to grow to $1.1 billion by 2030, up from $493 million in 2022. This represents a compound annual growth rate (CAGR) of 9.2 percent.

However, turning any forecast into reality often means embracing new technologies and ways of doing things. For metal buildings, this may include the widespread adoption of pressure-sensitive adhesive (PSA) tapes for a variety of sealing and joining applications throughout the structure.

What is a PSA tape?

In simple terms, a PSA is a type of adhesive that forms a bond with a substrate upon the application of light pressure. An adhesive can be coated onto a carrier material, such as a paper or polyester or polyethene terephthalate (PET) film, to create a tape. Anyone who has wrapped a birthday gift, masked a surface before painting, sealed a package for shipping, or made a quick repair around the home or on their vehicle has used consumer PSA tape. The technology behind PSA tape extends far beyond what one might find at their local big-box store. Its industrial applications are vast, and recent innovations have made it even more versatile.

Fine-tuned to application needs

The leading adhesive manufacturers produce thousands of PSAs, including rubber, acrylic, and modified-acrylic chemical formulations. This is because, in industrial settings, PSAs are often fine-tuned to very specific needs.

PSAs can be made to be easily removable, or to remain bonded for decades. They can be formulated with properties such as resistance to fire and heat, extreme cold, mold, UV light, fuels, and chemicals. Certain PSAs emit low levels of volatile organic compounds (VOCs), ensuring their compliance with consumer safety regulations.

Industrial tapes can be formatted to be single-coated (one layer of adhesive coated on a carrier), double-coated (two layers of adhesive on either side of a carrier), or as a transfer tape (a single layer of adhesive that separates from the carrier upon application to the substrate).

They can also be combined with functional materials which serve a specific purpose, such as flame-retardant materials, electrically insulating films, sound- and vibration-absorbing materials, and many others. They are available in varying lengths and widths and are often die-cut and laminated to a customer’s specification.

The array of possible combinations involving adhesive, tape formats, and functional materials is astonishingly vast. The ability to fine-tune a tape to a specific need is virtually limitless.

So, it is no wonder why this versatile product has been adopted for applications in industries including automotive, aerospace, appliances, electronics, healthcare, personal care, print and packaging, and transportation. Besides application-specific properties, PSA tapes are valued for their reliability, durability, and ease of use. In many industries, tapes are further valued as a replacement for metal or plastic fasteners or liquid-applied adhesives, helping manufacturers save weight and improve manufacturing efficiency and throughout.

Building and construction

The use of PSA tapes in building and construction has grown in recent decades.

A wide range of building materials now incorporate PSAs. They have gained prevalence in exterior building envelope applications such as weather stripping, flashings, exterior insulation, and finish systems (EIFS). They are also used in products such as vinyl siding and reflective roofing membranes. Similarly, the use of PSA tapes is increasingly common in a wide range of interior construction applications. These include mounting ceiling tiles, light fixtures, flooring tiles, kitchen backsplash tiles, decorative items, and functional items such as soap dispensers.

PSA tapes offer benefits for metal building construction applications as well, with new capabilities expanding the material’s performance and versatility.

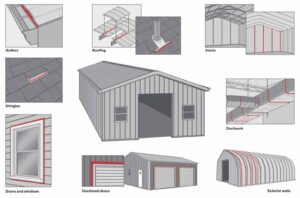

Metal building PSA tapes commonly feature a foam carrier and a single coating of adhesive. They are used in a variety of areas, including roofing and gutters, doors and windows, overhead doors, exterior walls, ductwork, and interior joists. Where large gaps exist or in areas prone to movement, tapes can be used to create vapor seals. They can also be used to create lap-joint seals in prefab wall panels or corrugated building panels or create flash breaks on building purlins and girt flanges.

Targeted innovations precisely serve industry needs

Climate change is adding new challenges to construction. So, to meet the needs of the metal building industry, PSA tape manufacturers are working to create formulations designed to stand up to severe temperature swings, drought conditions, damaging winds, and heavy precipitation. Their objective has been to create innovative solutions which are as reliable and durable in these conditions as any liquid-applied adhesive or mechanical fastening system while offering the incredible ease of use and versatility of tape.

One example is a “climate-resistant” formulation. The adhesive has been tested for installation temperatures down to -18 C

(0 F) with a service temperature of -40 C (-40 F). It performs well in high humidity/wet conditions and can be securely bonded to surfaces that tend to accumulate condensation, offering long-term durability even with regular exposure to harsh sunlight.

Metal buildings are proliferating for commercial and residential uses in more parts of the country, from the frigid north to the sweltering south. Manufacturers and contractors alike can rely on PSAs to save time and effort during construction (especially crucial as the construction industry looks for solutions to its labor shortage) and be confident in the adhesive’s durability.

As the metal building industry grows, PSA tapes will become indispensable to manufacturers and contractors alike. Their versatility, ease of use, and durability make them a valuable asset.

Rebecca Blose is business development manager for Avery Dennison Performance Tapes. As a 25-year engineering and quality influencer of technical PSA tape solutions, she focuses on strategic, innovative, and future trend design opportunities within the building and construction segment. Blose can be reached at rebecca.blose@averydennison.com or www.linkedin.com/in/rebecca-blose-1b761117/.

Notes

1 www.coherentmarketinsights.com/market-insight/metal-building-system-market-5459