Wind resistance is critical when designing buildings, particularly in areas prone to extreme weather. Metal roofing and light-gauge steel framing are popular in modern construction due to their durability and sustainability. However, their performance heavily depends on their ability to withstand gusts.

The importance of wind resistance

Strong winds exert various forces on a structure, including uplift, lateral pressure, and vibration, which can compromise the integrity of the building if not adequately addressed.

One of the primary concerns is roof uplift, where wind moving over the roof creates a suction effect that can tear panels away or even destabilize the entire structure. Similarly, lateral wind pressure on walls and framing can cause them to bend or collapse without adequate reinforcement.

Wind vortex effects—at roof edges, corners, and wall intersections—amplify the pressure in these vulnerable areas. These zones require extra attention during design and construction to ensure they can handle the concentrated forces. Additionally, high winds often induce vibrations in materials like metal, which can weaken connections over time if not accounted for in the design.

Ignoring wind resistance in building design can lead to costly and dangerous consequences. Structural damage, such as loose panels or collapsed walls, is just the beginning. Water intrusion through compromised roofing or walls can result in interior damage and mold growth. If more than 30 percent of a roof suffers damage, it is considered extensive wind damage. Over time, these issues increase maintenance costs and may lead to higher insurance premiums.

Metal roofing: Built to withstand the elements

Metal roofing has become a go-to choice for wind-resistant construction, especially in areas prone to hurricanes, tornadoes, high winds, and other extreme weather conditions. Its high strength-to-weight ratio and durability make it ideal for withstanding significant forces imposed by high winds.

Metal roofing can boost home value by six percent and lower heating and cooling costs. However, the performance and benefits of metal roofing in such conditions depend heavily on thoughtful design and proper installation.

Panel type and profile

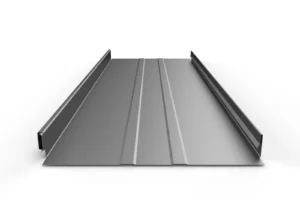

Metal roof panel design significantly impacts its wind resistance. Standing seam metal roofs—which feature concealed fasteners—offer exceptional durability against wind uplift. The absence of exposed screws or nails minimizes the risk of panels loosening or pulling away under suction forces. Corrugated and ribbed panels are also effective, provided they are secured with the proper fastening techniques and installed with precision.

Photo courtesy Grid Media Services

Fastening systems

Fasteners are crucial to the wind resistance of metal roofing. Screw-down panels must be attached using corrosion-resistant screws with appropriate washers to ensure a tight seal. For standing seam systems, clip fasteners allow the panels to expand and contract with temperature changes without compromising their structural integrity.

According to Joshua Riutta, owner of Mikku and Sons Roofing—a roof repairs and replacement company—the edges, corners, and overhangs receive the brunt of the damage, making reinforcements essential. Proper fastener spacing is critical—fasteners must be placed closer together at roof edges, corners, and ridges, where wind uplift forces are strongest.

Reinforcing vulnerable areas

The edges, corners, and perimeters are the most susceptible to damage during high winds due to the vortex effects created in these areas. Reinforcing these zones with thicker metal panels or additional fasteners ensures they can handle the increased wind pressure. Additionally, roof-to-wall connections should be given special attention to prevent separation under extreme wind loads.

Underlayment and substructure

While metal panels are the first line of defense, the underlayment and substructure also play a significant role in the roof’s wind resistance. High-quality underlayment adds an extra layer of protection against moisture if the outer panels are compromised.

Meanwhile, the substructure must be strong enough to distribute wind loads evenly across the roofing system. Purlins, rafters, and trusses should be designed and spaced to provide optimal support for the metal panels, particularly in high-stress areas.

Light gauge steel framing: resisting lateral and vertical forces

Light-gauge steel framing is an increasingly popular choice for commercial and residential construction due to its strength-to-weight ratio, precision, and recyclability. In wind-resistant design, it excels at resisting lateral forces while supporting vertical loads.

Photo courtesy Grid Media Services

Structural bracing

Diagonal bracing or shear panels are essential during high winds to prevent racking or collapse. Bracing can include strap bracing, flat steel plates, or steel shear walls designed to dissipate wind forces.

Photo courtesy Grid Media Services

Connection details

The integrity of the framing system depends on robust connections between walls, floors, and the roof. High-wind-rated screws and bolts—along with reinforced clips—ensure continuity in load transfer. Tie-down connectors and anchor bolts must be used to secure the framing to the foundation.

Load path continuity

According to Tyler Hull, founder of Modern Exterior—a roof replacement and repairs company—path continuity is one of the best strategies for ensuring maximum wind resistance. A continuous load path transfers winds from the metal roofing to the framing and down to the foundation. Discontinuities in this path can create weak points that compromise the structure.

Member sizing and spacing

The spacing of studs, joists, and rafters in these systems must account for wind loads. In high-wind zones, smaller spacing and thicker gauges may be required.

Photo courtesy Grid Media Services

Integrated design

A key principle in wind-resistant design is treating metal roofing and light-gauge steel framing as an integrated system rather than separate components. Collaboration between architects and structural engineers ensures compatibility between them.

Dynamic load sharing

Roof panels must work in tandem with the framing system to distribute wind loads evenly. For instance, clip systems in standing seam metal roofing should align with the structural framing to avoid stress connections.

Testing and certification

Both roofing and framing systems must meet standards like UL 580, Standard for Tests for Uplift Resistance of Roof Assemblies, and ASTM E1592, Standard Test Method for Structural Performance of Sheet Metal Roof and Siding Systems by Uniform Static Air Pressure Difference. Testing assemblies under simulated wind conditions ensures they meet or exceed performance requirements.

Building code compliance

Adhering to local and national building codes ensures structures are designed to withstand region-specific wind loads.

Designing for durability and safety

Designing for wind resistance is not just about meeting minimum code requirements—it is about creating structures that endure the worst conditions while maintaining safety and functionality. Builders can achieve high-performance, wind-resistant designs by integrating advanced metal roofing systems with robust light-gauge steel framing.

Jack Shaw, senior editor at Modded, brings a keen eye for design and innovation. With a rich background in covering architectural trends for multiple publications, he provides insightful commentary on the evolving intersection of architecture and advanced manufacturing.