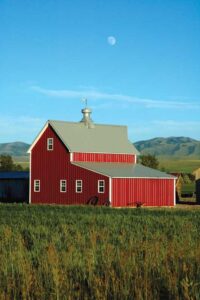

When a metal roof is specified on a project, it sends a clear signal the owner or tenant values longevity, durability, and return on investment (ROI). While providing peace of mind, metal roofs also deliver a highly desirable aesthetic.

Proper installation certainly correlates directly with the roof’s appearance and performance over the long haul; however, there is another critical factor: the coating specified for the substrate.

The selection of this coating cannot be an afterthought in either the design or installation phase of any project. Coatings affect everything from heating and cooling costs to long-term appearance and longevity, while helping to reduce the impact on the environment.

Thanks to advancements in material science, today’s coatings are engineered to deliver performance metrics never considered possible years ago.

Advancements in coating tech

The industry’s first cool coating was commercialized in 2001. Today, cool coatings contribute to continued growth within the metal roofing industry, shattering commonly held misconceptions about roofing choices.

This innovation incorporates infrared (IR)-reflective pigments with solar and thermal reflectance properties. Infrared light accounts for one of three light sources in the electromagnetic light spectrum with the other two being ultraviolet (UV) and visible light. IR accounts for approximately 45 percent of the sun’s energy.

IR-reflective pigments are specifically designed to absorb the sun’s rays in the UV and visible spectrums at a microscopic level. Simultaneously, a significant portion of the heat energy in the near infrared (NIR) spectrum is reflected.

The source of IR-reflective pigments in high-performance coatings for the building industry are either organic materials like titanium dioxide or the more commonly engineered inorganic compounds.

Investing in sustainability

Today’s cool coatings offer significant economic benefits and are often a better investment in the long term when compared to other roofing materials.

Day-to-day energy savings on hot, sunny days are where these differences are most evident or notable. The U.S. Department of Energy1 shared data showing that a conventional roof can exceed temperatures of 65.5 C (150 F) in such conditions. By contrast, roofing substrates using reflective coatings can be more than 10 C (50 F) cooler.

The thermal efficiency speaks for itself. Compared to traditional roofing, buildings with cool-coated roofs can see cooling demand in air-conditioned residential buildings decrease by 11 to 27 percent.2 Compared to standard coatings, cool coatings have a higher degree of solar reflectance. They also improve thermal emittance (how quickly the substrate “sheds” sunlight and heat).

For example, a standard black pigment has a total solar reflectance (TSR) value of about five percent. A black IR-reflective pigment can reflect about 50 percent of infrared energy, which increases the TSR to the 25 to 30 percent range.

Efficiency, return on investment (ROI), and aesthetics

What does all this mean for the building owner? These high-tech cool coatings lower building temperatures and reduce how much energy is needed for cooling purposes.

Luckily, architects and designers can embrace these sustainable options without sacrificing color and design. Plus, this technology helps to alleviate concerns about darker colors and heat absorption. Advancements in IR-reflective pigment technologies help to offset any heat absorption from specifying darker colors for a client’s project.

Further, advances in coatings technologies mean IR-reflective pigments are better able to resist color fade and corrosion. In addition, the structural integrity of the substrate is protected from warping, thermal expansion, and polymer degradation.

For the owner, cool-coated metal roofing substrates offer more comprehensive protection and are a better overall investment for the building envelope. Not only can these coatings match any design or color, but they can also greatly extend the life cycle of the roof itself.

Benefits beyond the building

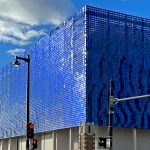

Roofing materials have a significant impact on the urban heat island effect, which is common in densely populated areas. This phenomenon occurs when a variety of factors equate to urban areas having higher temperatures than surrounding areas. Neighboring buildings with similar roofing materials, an abundance of concrete, vehicles, air conditioning systems, and limited tree coverage can all contribute to raising temperatures at the neighborhood and even the city level.

Since they absorb heat and radiate higher temperatures, traditional roofing materials can stifle cooler air, raising ambient temperatures around a building.

By contrast, a building with metal roofing using cool coatings will reflect much more of this heat and have less of an impact on area temperature. This is because the metal substrate does not reach the temperatures of traditional roofing products.

When planned deliberately, projects featuring multiple buildings will see a far lower cumulative effect in terms of urban heat islands. This difference is particularly valuable for planned communities and commercial campuses.

Cool roofs also benefit the immediate areas, reducing peak electricity demand and potential for power outages. They may even help to reduce smog from air pollutants, which is intensified by higher temperatures.

Specifying cool coatings

Metal roofing continues to be among the most popular options for both the commercial and residential markets. For clients keeping an eye on a project’s ROI, the investment is certainly worthwhile.

The benefits of cool coatings for metal roofing are well documented. In a five-year study of panels installed in South Florida, those covered with cool coating formulations retained 100 percent of their initial solar reflectance, thermal emittance, color, and gloss. Such results are highly encouraging for clients considering metal roofing in areas with subtropical climates, such as Florida.

High-performance coatings for roofing can withstand decades of punishing sun and severe weather, and they can do so while helping to preserve the structural integrity of both large and small buildings.

Notes

1 www.energy.gov/energysaver/cool-roofs

2 www.epa.gov/heatislands/using-cool-roofs-reduce-heat-islands

Gary Edgar is the architectural specification manager for PPG’s Building Products. He has been with the company for more than 25 years, with 17 years devoted exclusively to PPG’s Air-Dry Fluoropolymer and Build Restore Protect (BRP) coating systems. Edgar is a NACE certified coating inspector.